Endress+Hauser Conducta GmbH+Co. KG

Endress+Hauser Conducta GmbH+Co. KG

Dieselstraße 24

70839 Gerlingen

Germania

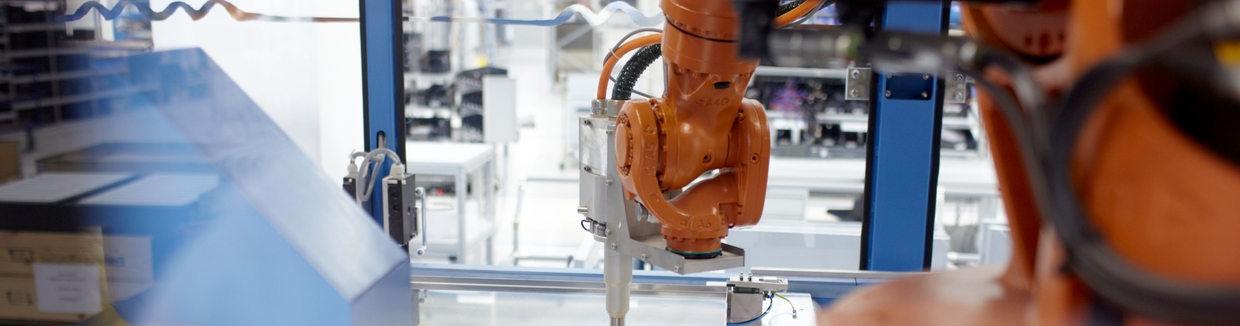

The production of our samplers and Liquiline System analyzers is optimized in every respect. The concept was developed in a simultaneous engineering process in close cooperation with R&D, Marketing, Logistics, Industrial Engineering and Production. All manufacturing steps and processes were simulated during the planning phase to make the workstations as ergonomic as possible.

Our modern production area is equipped with a powered rail system to hold flexible and movable tool trolleys for the assembling stations. The height of the trolleys is adjustable so that the picking distances for parts and tools are kept to a minimum. The production line also provides crane support for heavy loads to reduce the physical stress on the staff, leaving them to fully concentrate on precision device assembly.

Our samplers and analyzers are part of the Liquiline platform so their transmitters use exactly the same hardware and software as our Liquiline controllers for more efficient manufacture and simpler operation – it’s a win-win situation!

Endress+Hauser Conducta GmbH+Co. KG

Endress+Hauser Conducta GmbH+Co. KG

Dieselstraße 24

70839 Gerlingen

Germania