About surface thermometers

Non-invasive thermometers are used to measure the medium temperature by only touching the outer surface of a pipe, reactor or vessel. They can be used universally in all industries, but are ideal for heavy duty industrial processes with demanding process conditions. Especially for retrofitting measurements into existing systems for energy and safety monitoring or temporary measurements, non-invasive temperature sensors are the right choice as they can be flexibly positioned either at different points on the pipe or across different pipes in a plant.

Applications

A surface temperature assembly is ideal for demanding process conditions such as high flow velocities, high process pressures, highly viscous or corrosive media, abrasion, pigging or small pipe diameters. This makes them the perfect fit for heavy-duty industries, e.g. chemical and petrochemical; power and energy; mining, minerals and metals.

Benefits

- No direct contact with the process medium

- No risk of leakage

- No need for extensive engineering (e.g. thermowell wake frequency calculation)

- No need to shut down the process

- Easy to install, even retrospectively or for temporary measurements

- No impact on the steadiness of the flow

- No thermowell wear due to corrosive or abrasive media

Advanced non-invasive thermometer for demanding applications

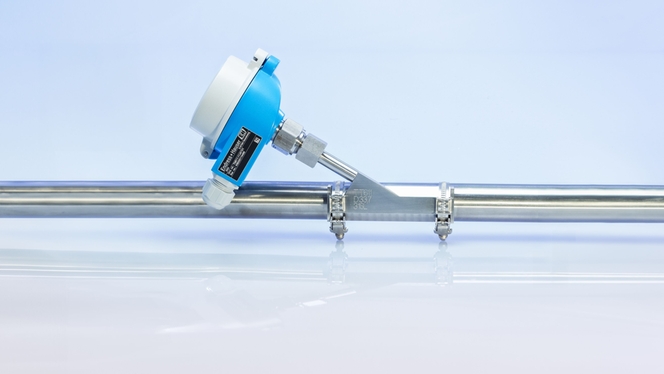

iTHERM SurfaceLine TM611 RTD/TC thermometer with highest accuracy

iTHERM SurfaceLine TM611

for energy and safety monitoring, retrofitting or temporary measurements

Fundamental surface thermometer for basic monitoring applications

iTHERM SurfaceLine TST602 RTD thermometer

Advanced non-invasive thermometer for demanding applications

iTHERM SurfaceLine TM611 RTD/TC thermometer with highest accuracy

iTHERM SurfaceLine TM611

for energy and safety monitoring, retrofitting or temporary measurements

Fundamental surface thermometer for basic monitoring applications

iTHERM SurfaceLine TST602 RTD thermometer

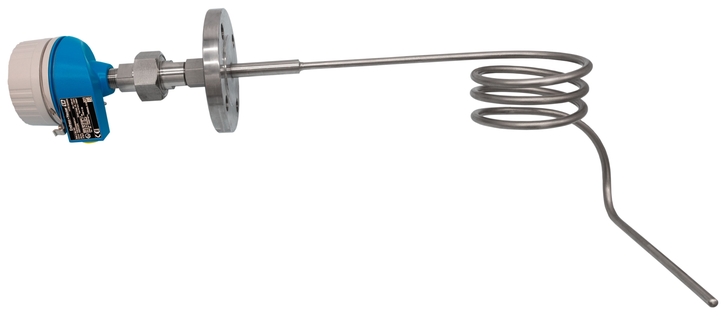

Customized surface thermometers for furnaces, fired heaters and heat exchangers

By measuring the temperature of the pipe skin, these skin point assemblies are used to check for build-up on the inner wall of the pipe. Designed and installed to customer specifications, they ensure optimum thermal continuity even under the most severe operating conditions, such as vibration, corrosion, or relative movement due to differential thermal expansion. To configure a customized skin point thermometer please contact your Endress+Hauser sales representative.

Technical specifications

- TC sensor with reinforced tip

- Wide range of high-grade materials

- Compensation for thermal distortion with optimized expansion coils

- Compatibility with existing process connections

- ATEX Ex-d certification for the entire device

- Bendable sensor sheath

- Different types of pipe connections: wedge shape, screwed in or bolt-in connection, fixed guiding brackets or clips, custom-shaped pad

Articole

Descoperiţi resurse suplimentare

.jpg)