Central beverage supply systems at large-scale events

The Picomag Inline electromagnetic flowmeter from Endress+Hauser installed in the Pschorr Oktoberfest tent in Munich

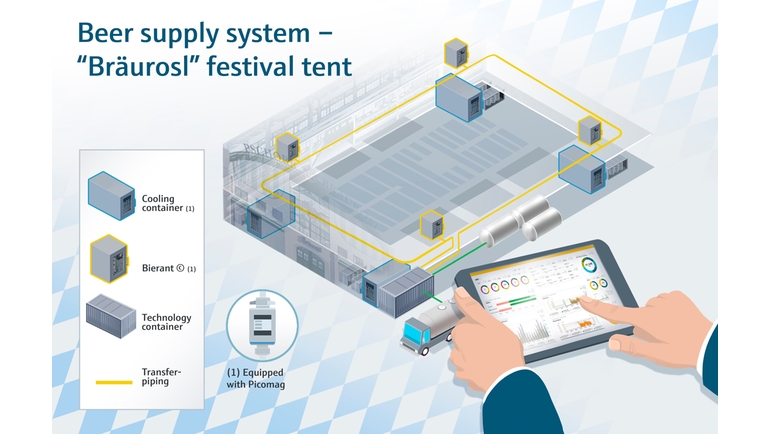

Since 2010, the Paulaner Brewery Group has been using underground ring pipelines to supply beer to the Oktoberfest tents. This year, the brewery Pschorr installed a world premiere in the new Bräurosl tent: the first aboveground vacuum isolated piping (VIP) for the central beer supply system installed directly in the tent. Endress+Hauser measuring instruments reliably monitor most of the relevant parameters for the beverage supply.

Results

-

14,400 liters of beer are fed each hour to six taps. Eight Picomag Inline flowmeters, located in four so-called Bierant©, monitor the amount of beer that flows from the transfer piping to the taps.

-

30 other Picomag Inline flowmeters monitor the flow of the non-alcoholic beverages from the keg to the tap.

-

50% less installation and deinstallation times thanks to the modular system.

-

Easy integration into common fieldbus systems and simple setup of cloud connectivity thanks to the integrated IO-Link interface with all Picomag Inline.

Customer challenge

The existing underground ring piping system is tied to the location and subject to weather conditions. This eliminates any flexibility in the designing the site and makes it difficult to carry out any repair or maintenance work.

Realization

The amount of beer and non-alcoholic beverages that flows to the taps is monitored by 38 Picomag Inline, the pocket-sized electromagnetic flowmeter from Endress+Hauser. The Picomag Inline also simultaneously monitors the temperature and conductivity, both important values for the CIP cleaning. The flowmeter furthermore comes with an integrated IO-Link interface as a standard feature. Cloud connectivity is also simple to establish.

-

Produse de specialitate

- Conceput pentru aplicatii solicitante

Excelenţă tehnică

Simplitate

Variabil

| Colecții FLEX | Excelenţă tehnică | Simplitate |

|---|---|---|

Colecție Fundamental Îndepliniți-vă nevoile esențiale de măsurare |

Excelenţă tehnică

|

Simplitate

|

Selecţie Lean Gestionați-vă cu ușurință procesele de bază |

Excelenţă tehnică

|

Simplitate

|

Colecție Extended Optimizați-vă procesele cu tehnologii inovatoare |

Excelenţă tehnică

|

Simplitate

|

Colecție Xpert Stăpâniţi cele mai dificile aplicaţii |

Excelenţă tehnică

|

Simplitate

Variabil |

%20The%20economical%20flowmeter%20for%20process%20quality%20control%20and%20monitoring%20-%20PP01.jpg)