Beer is brewed using naturally grown products that vary from year to year and from harvest to harvest. The brewer must react to these changes to produce a beer of stable quality, and moreover, the beer must also taste the same year after year in order to meet the customer's expectations. To hit this moving target, a lot of experience is necessary. And that is the art of brewing beer.

Date esenţiale

~2

billion hectolitres

of beer were produced worldwide in 2019. Consistent and stable product quality is key for all breweries. Benefit from Endress+Hauser’s competence and experience to achieve this goal. Sources: www.statista.com

Learn more about how to improve your brewing processes

Brewhouse

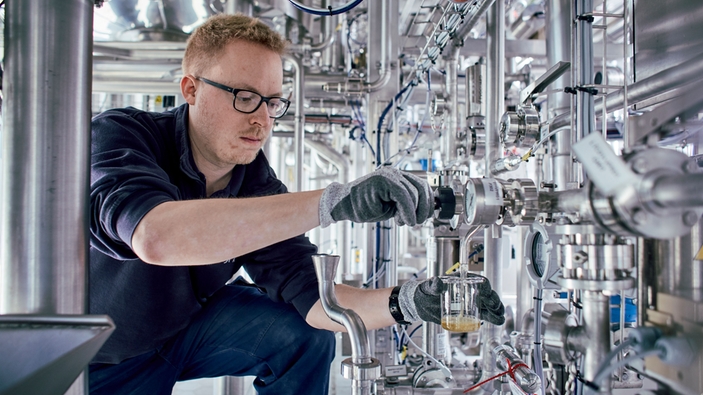

Efficient conversion of starch into malt sugar must be ensured. To find the right moment within the certain processes, innovative and accurate measurement technologies are crucial.

Our expertise in the field

Endress+Hauser offers the largest product portfolio to optimize every single processes in your brewhouse.

- Ensure highest reliability and accuracy using non-glass pH sensors like CPS77E with Memosens technology and retractable holders.

- To see the real yield, the multi-frequency Coriolis mass flowmeter Promass Q provides temperature compensated flow, totalized value and totalized Brix or Plato° values even in entrained gas applications.

- Rely on highest reliablity in your mash tun level measurement using the temperature compensated Deltapilot FMB50 hydrostatic level sensor . Remote electronics make access easy.

- Optimize raw material usage by adding liquified adjuncts and dextrose with high accuracy. The Coriolis mass flowmeter Promass F100 provides the best temperature stability and precise measurement.

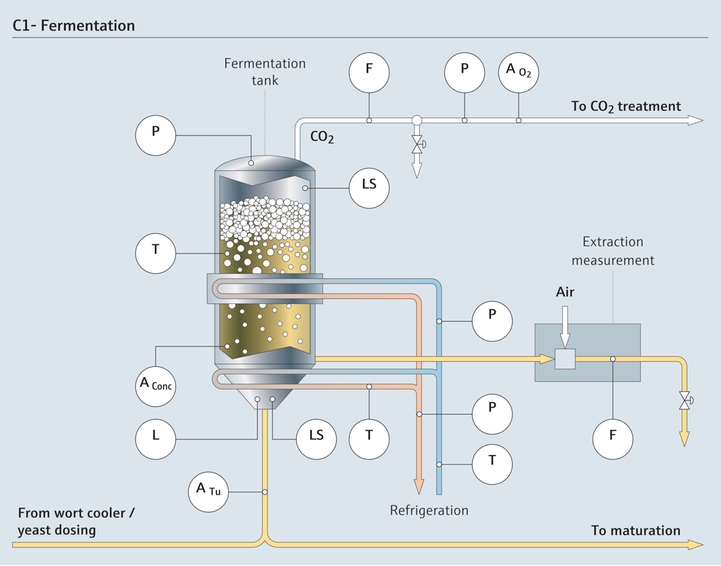

Fermentation

The goal of fermentation is to convert the malt sugar into alcohol. Reliable measurement of temperature, extract, and alcohol as well as monitoring the fermentation process are crucial to ensure consistent quality batch after batch.

Our expertise in the field

High quality RTDs in hygienic design combined with ultra-fast response time guarantee optimum temperature control. Continuous measurement of all relevant parameters in the fermentation process provides laboratory-accurate and reliable information in real time, thus enabling precise process control.

- Improve your temperature control with our digital thermometer iTHERM TM411.

- Optimize your fermentation process with the multi-sensor measuring device Fermentation Monitor QWX43.

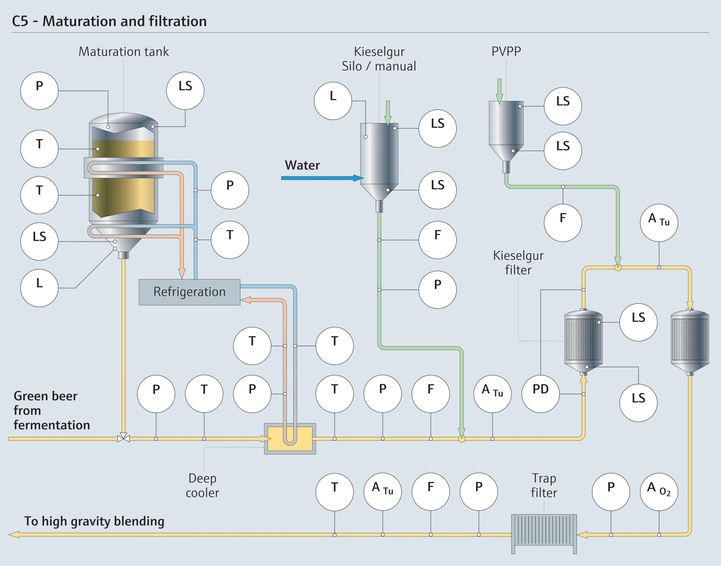

Filtration

The major challenge of the conventional filtration process is related to the diatomaceous earth filtration because the diatomaceous earth can vary in quality. It is problematic for handling and disposal since it is hazardous and generates large amounts of effluent.

Our expertise in the field

Differential pressure is a common indicator for filter performance. Conventional DP transmitters or electronic DP systems provide the needed reliability.

- Improve reliability and optimize your filter performance with the electronic differential pressure system Deltabar FMD71.

Color based in-line detection of beer types

Breweries often produce many different types of beer. It is quite a challenge to keep a clear overview in production to ensure proper filling.

Our expertise in the field

To ensure production runs smoothly and to reduce beer loss, manufacturers must, where possible, distinguish the individual beer types automatically and directly inline. Dual-channel photometers are used for the measurement, making it possible to analyze color absorbance according to EBC guidelines. Together with a conductivity measurement, the individual types can be identified.

- Rely on our optical sensor OUSAF22 for a precise inline color measurement.

- Use the digital conductivity sensor Indumax CLS54D.

Securing beer quality through microbiological testing

Microbial contamination with spoilage bacteria can occur at multiple stages of the brewing process. This can affect raw materials, the product itself, or the brewing environment. Therefore, testing critical points such as the fermentation tank, the bottling line or the brewing water is crucial. Traditionally, detection of spoilage bacteria has relied heavily on time-consuming laboratory testing.

However, there’s a more efficient solution: the Endress+Hauser BioSense Analysis System. This innovative system enables PCR-based detection of spoilage bacteria, microbial contamination, and even pathogens. With its compact design and simple workflow, the Device BAB00 enables for immediate on-site analysis, significantly reducing response times and ensuring swift corrective actions. This approach revolutionizes quality control in the brewing industry, enhancing both quality and efficiency.

Cleaning in place (CIP) optimization

CIP concentration is critical to food safety but also has big impact on the use of detergent and wastewater costs.

Our expertise in the field

Highly accurate conductivity measurement ensures the exact calculation of the required concentration. Level measurement of aggressive chemicals can be solved using different options depending on tank size and user preference.

- Ensure minimal beer loss during beer/water transitions thanks to the very fast temperature compensation of our conductivity transmitters.

- Rely on the most common measuring principles hydrostatic level measurement and radar level measurement.

- Discover more innovative sensor technologies to optimize your Clean-In-Place (CIP) process.

Benefits

Trust our reliable instruments for quality control and quality assurance in your brewery, that supplies the necessary data for ideal processes, supports suitable solutions for tracking and tracing your beer and minimizes product losses. Our experienced team of industry and application experts helps you select the right process instrumentation for your critical parameters.

Date esenţiale

52 weeks

stable product quality and processes thanks to best-fit instrumentation for your critical parameters

Date esenţiale

30%

less water and chemicals used in your CIP process

Date esenţiale

100%

compliance to industry standards and regulations

Our offering

Endress+Hauser is here to help you run your brewing process consistently on a high-quality level day and night. Our state-of-the-art sensor technology supports the brewing industry. Constantly improved accuracy of process sensors, along with high repeatability enables you to run your process in the most efficient manner. Our offering stands for:

- Stable beer quality

- Reliable process instrumentation

- Efficient use of raw materials